- Warranty:

-

1 year, 1 Year

- After-sales Service Provided:

-

Field installation, commissioning and training

- Place of Origin:

-

Fujian, China

- Brand Name:

-

GEILI

- Dimension(L*W*H):

-

2300*2300*1650 mm

- Power(W):

-

Customized

- Product name:

-

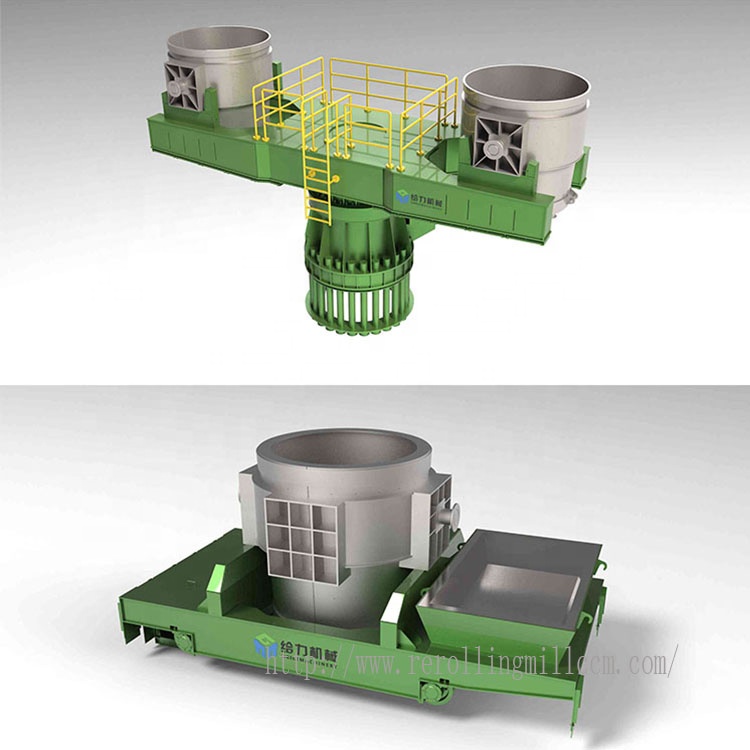

Metallurgy Equipment Foundry Pouring Steel Ladle for Casting

- Application:

-

Steel Metallurgy Industry

- Dimension:

-

2300*2300*1650 mm

- Usage:

-

Steel Molten

- Feature:

-

Low Noise

- Material:

-

Steel

- Certification:

-

ISO9001: 2015, ISO9001:2015

- Delivery Time:

-

60 Days

- Condition:

-

New

- Voltage:

-

380V

- Weight:

-

5.5 tons

Product Description

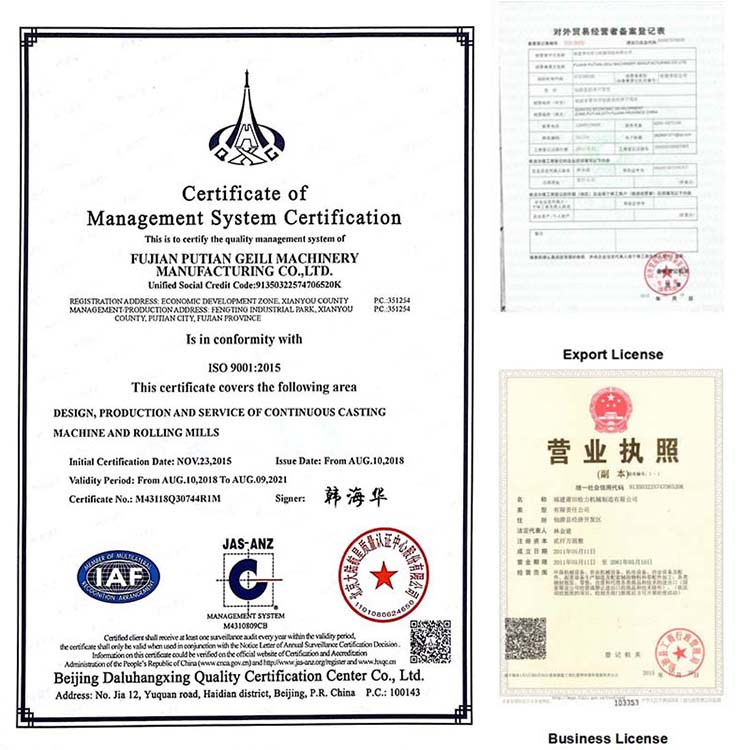

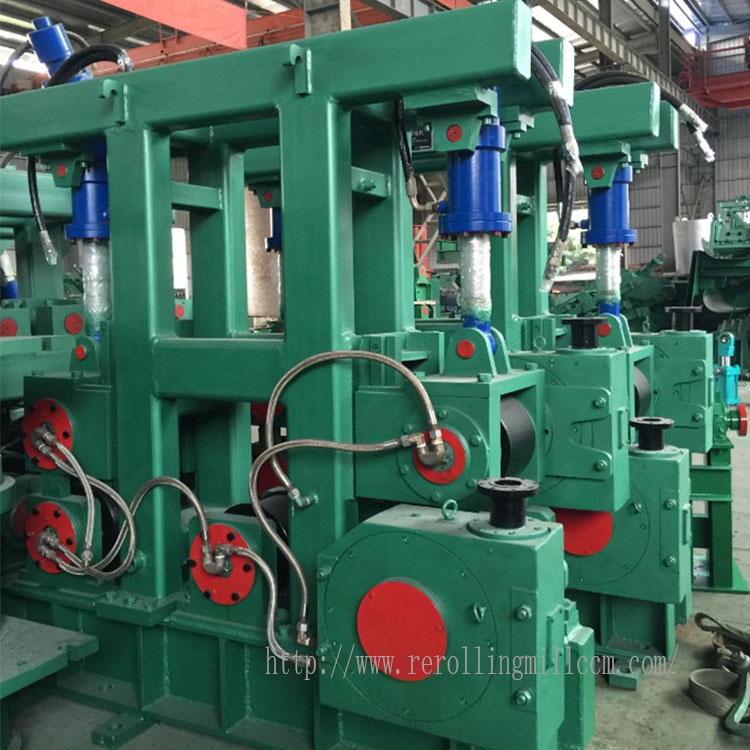

Casting steel ladle manufacturer is important device in steel making. It used for pouring operations, after receiving the liquid metal in the blast furnace, transported by road to the mold at the pouring.

Advantage:

| 1.Resistance to burning hot metal ladle. |

| 2.Multi-purpose hot metal ladle. |

| 3.Safe and reliable design. |

| 4.Easy operation. |

Components:

旋转臂

rotary bearing

transmission device.

Company Information

FUJIAN PUTIAN GEILI MACHINERY MANUFACTURING CO.,LTD

wasfounded in 1995,formerly known as Xianyou Rolling Mill Manufacturer.In 2001,merged with Xianyou Bangtou Mill Roll Manufacturer.In 2008,wefocused on continuous casting and rolling production line equipment.In 2011,the company reorganized and established FUJIAN PUTIAN GEILI MACHINERY MANUFACTURING CO.,LTD,whichengaged inmetallurgical equipment,mainly in steel-making,continuous casting andcompleterolling production line research and development,design,manufacturing,installationand general contracting services.

Our service:

1) Providing professional proposal of suitable production line as per customers' invest and capacity requirement

2) Providing turn-key service of designing, manufacturing, installation and commissioning for the whole production lines to meet customers requirement

3) Providing foundation layout and arrangement diagram for your plant

4) Providing technical support. We will send various technical staff to the site until the final products are meet to customers' own request.

5) Good after-sales service will be provided. Our long-term technical service will be provided if you want to adjust the production line, develop new products or improve the equipment.

Quality Control:

Quality control (QC) is a procedure or set of procedures intended to ensure that a manufactured product or performed

service adheres to a defined set of quality criteria or meets the requirements of the client or customer.

Finish Product QC

Ensure all the dimension and technical process are correct

Drawing QC

Ensure all the drawing are inspected by Profesional Enginners

Shipping QC

Ensure the product pass to customer are optimum and correct quantity.

Packing & Shipping

-

China Supplier Automatic Continuous Casting Mac...

View Detail -

Wire Rod Steel Straightening Machine for Rebar

View Detail -

CCM Steel Billet Continuous Casting Machine Chi...

View Detail -

High Quality Continuous Concast Metal Casting

View Detail -

Continuous Casting Machine Steel Billet CCM

View Detail -

CNC Casting machine CCM High Quality Continuous...

View Detail